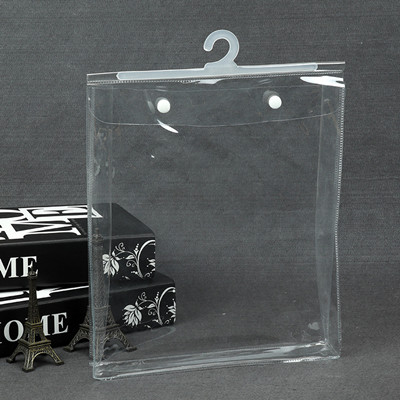

Production methods of PVC bags:

The production and processing methods of PVC bags are usually high-frequency hot pressing or sewing. High-frequency hot-pressed PVC bags. After the PVC film is cut into pieces, it needs to be silk-screened first (PVC is generally silk-screened), and then hot-pressed with a high-frequency machine. Generally, a custom-made copper mold is required. Production. Hot-pressed PVC bags can be pressed into PVC sleeve bags, PVC welted bags, PVC toothless zipper bags, PVC handbags, PVC ziplock bags and other styles. After the sewing PVC bag is cut and printed, it is directly sewn with sewing machine thread such as flat car or high car. Generally, there are nylon zippers and other accessories.

Advantages of PVC bag:

The pvc zipper bag is very good-looking. Although it is small, it has a great effect. It can hold small daily items, as well as gifts, cosmetics, stationery, etc. It is very convenient; the medium-sized pvc zipper bag can be used as a document bag. It can hold some office supplies, such as documents, USB flash drives, mobile phones, etc.; the pvc zipper bag in the style of a handle bag, which can be hand-held or placed directly, and is kept in a sealed state, which is more novel, fashionable and practical; the pvc zipper bag is beautiful and fashionable And practical, it can also be used as promotional items or gifts.